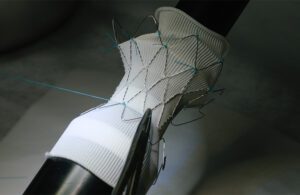

Each Medtronic Harmony valve is sewn by hand to attach laser-cut pig tissue to the nitinol that makes this minimally invasive heart implant possible.

Medtronic’s Harmony transcatheter pulmonary valve (TPV) is made of nitinol wire, polyester and laser-cut pig tissue, all sewn together by hand. [Photo courtesy of Medtronic]

Medtronic’s Harmony transcatheter pulmonary valve (TPV) design is paying off after engineers solved a delivery catheter recall and relaunched the system this year.

The Harmony TPV uses pig tissue, shape-memory alloy nitinol and manufacturing techniques old and new to solve a special challenge for children and adults.

The catheter-placed Harmony valve offers a minimally invasive way to improve the flow of blood to the lungs and delay open-heart surgery for congenital heart disease. Congenital heart defects are present in about 40,000 babies born each year, making it the most common type of birth defect.

Harmony TPV is for patients with right ventricular outflow tract (RVOT) anomalies and severe pulmonary valve regurgitation. After the heart pumps deoxygenated blood into the lungs, that blood leaks back into the heart’s right lower chamber instead of being pumped out to the rest of the body.

Garrett Pilcher is Medtronic’s VP of clinical research for Structural Heart. [Photo courtesy of Medtronic]

“It can start as a small leak, but the blood starts going backward through the valve … and starts backing up within the body,” Garrett Pilcher, Medtronic VP of clinical research for Structural Heart, said in an interview with Medical Design & Outsourcing.

Patients will start feeling sluggish and face a variety of infections and other problems due to lack of oxygenated blood flow through the body.

“Harmony was the first device approved by FDA for this indication, and before this patients were getting multiple procedures over time, ultimately open-heart surgery,” he said. “… It was a first-of-a-kind design to get into the right ventricular outflow tract for these patients that didn’t have a minimally invasive option prior to that.”

Medtronic recently released two-year results for 86 patients with Harmony TPV implants. About half received the 22 mm valves and the other half received 25 mm valves. The study showed no vascular injuries requiring intervention and only 3% of patients with more than mild pulmonary regurgitation.

“We’re not seeing severe backflow, which was the original issue we were trying to solve,” Pilcher said.

Though surgeons will want to see 10 or 15 years of durability to compare Harmony against open-heart surgery, the study shows at least two years of durability — and counting.

“We’re seeing no detriment or the valve starting to not function as well,” Pilcher said.

How Medtronic makes the Harmony valve

Each Medtronic Harmony valve is sewn by hand with 2,200 to 2,500 stitches. [Photo courtesy of Medtronic]

Workers in Tijuana, Mexico, sew each Harmony valve by hand. Each valve takes 2,200 to 2,500 stitches to attach the knitted polyester and laser-cut pig heart tissue to each other and to six separate nitinol wire struts.

Those self-expanding wire struts are not welded together so they maintain their flexibility, allowing for a better seal on both ends of the valve to prevent blood leaks.

The thin, pericardial pig tissue used in the valve leaflets and inner wall were also selected for flexibility. Medical-grade pig tissue suppliers are owned by the parent companies of the same slaughterhouses that make sausage and pork chops; one example is Johnsonville’s Sustainable Swine Resources.

Meanwhile, Medtronic manufactures the delivery system in Massachusetts. Final assembly takes place in Galway, Ireland.

Related: How nitinol is made for medical devices

Harmony’s origins

Before Harmony TPV came the Melody TPV. Melody was the first transcatheter valve implanted in a human in 2000 and won FDA approval in 2010.

“As we got into that space and started treating more Melody patients, what we learned was there was this analogous indication of patients that weren’t appropriate for Melody, but still didn’t have an option besides open-heart surgery,” Pilcher said. “It was actually through our Melody experience that we learned. And a lot of it comes down to lifetime management. I think what we’re going to see in the future is that these devices will be used in conjunction with each other.”

The Melody implant is a bovine jugular vein valve with a platinum-iridium frame. Despite Medtronic’s experience with the balloon-expandable Melody valve, it decided against balloon expansion for Harmony.

“Through testing, we learned [balloon expansion] in the RVOT that doesn’t always work,” he said.

The shape memory properties of the nitinol wire struts in Medtronic’s Harmony transcatheter pulmonary valve (TPV) allow it to collapse down into a catheter for delivery. [Photo courtesy of Medtronic]

Instead, Medtronic turned to nitinol’s shape memory properties, which allow it to be compressed into a catheter for delivery to the heart, where it expands back to its designed shape and anchors to the RVOT.

“You’ve got a lot more flexibility longer term that you need to be able to deal with in order to anchor the device long term in these patients that may have had prior repairs,” Pilcher said.

That flexibility is paying off as Medtronic considers future congenital indications and its work in TAVR, mitral and tricuspid valves, Pilcher said.

“We’re building on experience that shows it’s better to build the right device for the patient regardless of your expertise, as opposed to trying to find one valve that you can kind of shove everywhere,” Pilcher said. “Purpose-built devices are important.”

Related: How Medtronic uses nitinol to improve the structure and effectiveness of heart devices

Harmony’s launch, recall and relaunch

Medtronic’s Harmony TPV won FDA breakthrough device designation for the treatment of pediatric and adult patients with severe pulmonary valve regurgitation in March 2021. Beyond delaying open-heart surgery, the valve has the potential to reduce the total number of procedures a patient will face though their lifetime.

“The Harmony TPV provides a new treatment option for adult and pediatric patients with certain types of congenital heart disease,” Dr. Bram Zuckerman, director of the Office of Cardiovascular Devices in the FDA’s Center for Devices and Radiological Health, said at the time. “It offers a less-invasive treatment alternative to open-heart surgery to patients with a leaky native or surgically-repaired RVOT and may help patients improve their quality of life and return to their normal activities more quickly, thus fulfilling an unmet clinical need of many patients with congenital heart disease.”

In March 2022, Medtronic initiated a recall of the catheter delivery system used to place the Harmony implants after complaints that the capsule at the end of the catheter could break during implantation. At least one injury was reported and the FDA designated the recall as Class I, the most serious level.

“We essentially weren’t getting the bond that we needed [due to] a variety of issues, including supplier material changes over time,” Pilcher said. “The engineers had to work to develop a better bond, a polymer-molded bond.”

The fix didn’t include any changes to the Harmony valve itself, and Medtronic won approval to relaunch the system in February 2023.

“The relaunch of Harmony TPV underscores our continued commitment to advancing solutions for all people who experience heart disease,” Medtronic Structural Heart and Aortic President Nina Goodheart said at the time.

The system also won Japanese regulatory approval this year through the Harmonization by Doing (HBD) collaboration of the FDA and Japan’s Pharmaceuticals and Medical Devices Agency (PMDA).

“They’re willing to share information about their reviews in order to hopefully expedite but better educate both groups,” Pilcher said. “Their decisions are independent, but they share information: a lot of discussion about the bench testing and the animal work in particular. The goal is to try and move reviews along consistently. We’ve seen in particular with Harmony a great partnership between PMDA and FDA.”

The similar names of the HBD program and Medtronic’s Harmony valve are only a coincidence, Pilcher said, and Medtronic has had other products move through HBD.

Medtronic has since launched Harmony TPV in Japan and has a “wide-scale push” on training with sights set on Europe and the Middle East, Pilcher said.

“We have a massive focus right now in trying to get this into other countries, underserved countries, everywhere we can get it,” he said. “… Hopefully, we’ll span the globe, and any patient that needs this will eventually have access.”

Related: Why Affera’s cardiac ablation technology is worth $1B to Medtronic