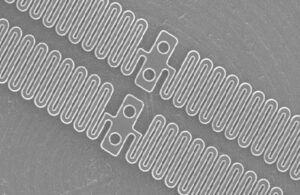

This nitinol thin film actuator made by Acquandas with a film thickness of 50 µm can pull 550 times its own weight. [Image courtesy of Acquandas]

Acquandas is a thin-film device manufacturer that’s now partially owned by brain-computer interface developer Synchron.

Rodrigo Lima de Miranda founded Acquandas in 2012 based on microsystem technology he developed for his doctoral thesis, where he was trying to develop a shape memory material made with thin-film deposition.

The Kiel, Germany-based contract manufacturer now uses the Nanolab cleanroom facilities at Kiel University and is growing its team of around 22 employees.

Beyond neurotech applications like Synchron’s Stentrode, the Acquandas technology has promising potential for cardiac ablation, renal denervation, opthamology, nerve stimulation, passive microimplants, microneedles, and smart actuators and springs, Lima de Miranda said in an interview with Medical Design & Outsourcing.

Related: New Synchron CTO Riki Banerjee on BCI manufacturing and outsourcing

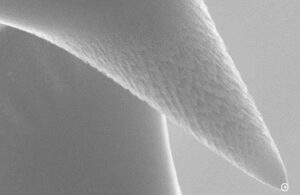

This nitinol microneedle made by Acquandas is only 20 µm tall.

The Acquandas microsystem technology utilizes a vacuum environment with UV lithiography, magnetron sputter deposition (a type of physical vapor deposition) and wet etching to create and fabricate devices. It’s the same technology used for MEMS (micro-electromechanical systems) manufacturing.

Acquandas additive manufacturing uses nitinol, titanium and alloys of magnesium and iron as base materials for varying properties such as mechanical stability, flexibility, crimpability, self-expansion (for a catheter-delivered implant, for example) or bioabsorbability. Then Acquandas can layer on other elements and compounds like gold or silicon monoxide to act as electrodes, isolators, temperature sensors or magnetics.

Lima de Miranda said benefits of the microsystem technology include miniaturization, design freedom, superior mechanical properties, increased radiopacity, cost efficiency, additional functionality, rapid prototypying, microstructured surfaces, excellent biocompatibility and simple alloy engineering.

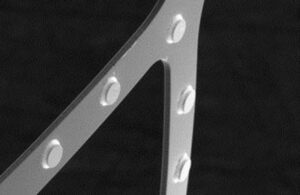

Layering tantalum on top of a 10 µm-thick nitinol stent as seen here can increase its radiopacity for better visualization during placement. [Image courtesy of Acquandas]

“With our technology, this material is so pure because we are coming from a gas phase — we don’t have carbides and defects on the film — and these mechanical properties are much superior than the standard tools,” he said.

When dealing with miniaturized devices, the company’s manufacturing equipment in one case was able to fit 30,000 devices on a single, 6-in. production wafer (though the company works with larger wafers when needed).

In the decade-plus since founding Acquandas, Lima de Miranda has worked on research and experimentation to develop the technology for mass production while building its client list to more than 50.

“This deal with Synchron shows that we are ready for the market,” he said.

Related: Opening the brain’s secret back door: A conversation with Synchron co-founder and CEO Dr. Tom Oxley