How to find the right balance between performance and patient comfort in wearable device adhesion.

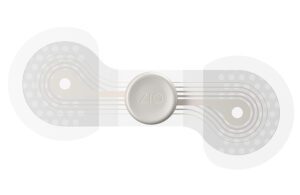

iRhythm’s next-generation Zio cardiac monitoring patch can be worn for up to 14 days. [Photo courtesy of iRhythm]

iRhythm’s next-generation Zio cardiac monitoring patch is smaller, lighter and thinner — three qualities that also assist the wearable device’s adhesion.

Adhesion is a one of the leading challenges for wearable device developers. iRhythm Chief Technical Officer Mark Day discussed how his team designed the latest Zio patch to balance performance and patient comfort.

“So much of what we want to do is try and think about unmet needs and patient monitoring,” Day said in an interview with Medical Design & Outsourcing. “It’s really about raising the bar of performance by miniaturizing to ensure that we can get an already very compliant device even better.”

1. Lighten the load with miniaturization

“When you’re thinking about an adhesive and getting an adhesive to stick in a comfortable and compliant manner, you want to reduce the force on that adhesive, both peel and shear forces,” Day said.

iRhythm reduced the size and overall weight of the device housing in the middle of the patch to minimize the force of gravity that’s constantly pulling on the adhesive.

“From an adhesive and performance perspective, the lower the weight, the lower shear forces and peel forces on the adhesive, the better off you’re going to be. And that’s that’s kind of just generally true,” he said.

The new device is 22% thinner and nearly 60% lighter than the last generation, aided in part by semiconductors that are smaller, more powerful and more efficient. The next-generation device also has a smaller battery.

Previously: How iRhythm sought to outdo the old-school Holter monitor

2. Less power is more

“For a wearable, the size of the battery is probably the biggest component for driving the overall volume of the device,” Day said.

That fact (which is also often true for other miniaturized and implantable devices) offered another opportunity to reduce the device’s size and weight. The increased energy efficiency of modern sensors and other components helped right from the start, but the iRhythm team challenged themselves further to design the latest generation with double the endurance and half the battery size — roughly one coin cell battery.

“That’s a very common, inexpensive, readily capable and very shelf-stable energy storage mechanism, but it’s not terribly energy dense. … It gives you a form factor to target,” Day said. “That’s effectively how we approached it: How do we create a medical device — a biosensor, an ECG ambulatory monitoring device — that is the size of one coin cell? And that’s exactly what we did.”

3. Find the right balance

iRhythm designed its latest Zio patch with an asymmetrical adhesion surface. [Photo courtesy of iRhythm]

“One of the things we did for the first time — and this is a unique feature compared with other wearables — is to introduce a dermal adhesive structure that is not symmetric. It’s actually asymmetric,” Day said. “It has a portion of it that is a little bit more adhered upward and a portion that’s a little bit more adhered downward as you’re looking at a patient’s chest.”

The team designed the adhesive structure with subtle features to keep the patch in place based on what iRhythm has learned about adhesive performance and patient comfort over the years.

“That was all done with this idea of thinking about where forces, largely gravitational forces would pull over time, and where it was a little bit strategically more powerful to put in adhesive capabilities and surface area.”

4. Sweat the wet stuff

With 6 million Zio XT devices produced over the years, thousands of patients are wearing iRhythm devices on any day of the year. That gives the device developer plentiful experience in adhesion in countless situations, including hot, sticky days when patients sweat the most.

“The type of adhesive we use leverages some great capabilities in terms of moisture absorption,” Day said of the Zio Monitor’s hydrocolloid adhesive. “But what was happening is that the moisture was effectively getting caught between the skin of the patient and the device itself in the adhesive, and it really didn’t have anywhere to go.”

A patient’s skin can reabsorb that moisture — “The skin is really a pretty remarkable organ in that sense,” Day said — but iRhythm found a better solution.

“What we did was introduce perforations in the housing — that’s a patented design feature now — to allow that moisture to transpire, which is more effective and comfortable and in fact more meaningful way to get moisture off and out of the device-patient interface to allow the adhesive to maintain more bond to the patient,” Day said.

Moving that sweat away from the patient and adhesive prevents the carboxymethylcellulose in the adhesive from absorbing the moisture, which changes the geometry of the adhesive and how it adheres to the patient.

“The intent was to make sure that the moisture could get out and ultimately not just perform better, but also be more comfortable for the patient,” Day said.

5. Adapt to environmental changes

No matter where you live, you’ve probably noticed hotter and hotter weather trends. It’s not your imagination. Temperatures continue to set new extreme records across the globe as carbon-emission-fueled climate change accelerates.

“We’re entering into progressively warmer and hotter summers, which we know is a time of year, for example, where patients certainly are challenged to wear adhesive devices, as they’re sweating more while living their lives,” Day said. “We want them to experience the environment and have a very good and secure and very patient-compliant experience.”

“It was a challenge even 20 years ago to figure out how to adhere things to people — not just in the summer, but any time of year,” he later continued. “… Things are only getting warmer.”

Related: An even larger medtech supply chain shock looms beyond the pandemic: climate change

6. Stop searching for the perfect solution

“There is no perfect adhesive out there,” Day said. “And you can stop trying to find it.”

Hydrocolloid adhesive was originally designed for plasma absorption in wound dressings, and over time has proven its adhesion capability, medical-grade utility and patient compliance, Day said.

“It’s this mixture, a very careful balance of adhesion and skin compatibility, which is always something that we’re striving to be better at,” Day said.

He encouraged device designers and engineers to experiment and be curious while thinking about the patient experience and device performance.

Silicone adhesives are “wonderfully compliant with patients but just doesn’t stick very well,” Day said. [For} a diagnostic device that you’re trying to ensure can record reliably as a patient’s living their lives and doing it naturally, whether that’s showering, exercising, sleeping, running, chasing after the kids or putting on their shirt … you have an obligation as an engineer to figure out a way to make the device work well. And that might mean pulling back from some of these kind of gentler adhesives, because the reality is they don’t perform very well.”

On the other hand, the strongest, most secure adhesive you could design is likely going to cause irritation, allergic reactions and other patient discomfort.

“It’s a balance you have to try and figure out, and the balance really depends on the specific application and how much you’re trying to support from a weight-wise perspective,” Day said.

“But you do have to tweak things to make sure that it all works,” he continued. “And it’s pretty hard to get it right in one generation — so a lot of iteration.”