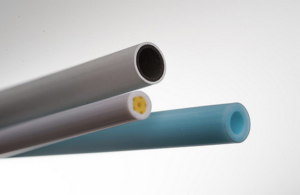

Coextrusion is the process of pressing two or more materials into a single piece of tubing.

Coextruded tubing is commonly used in the packaging and medical device industries. For example, multi-layered extruded tubing can be used for drug delivery applications, including insulin delivery, angiography and pain therapy.

Coextruded tubing can also be made into a catheter or to form dual layer tubing. Each tube can be covered with different coatings, such as lubricious or hydrophilic, depending on the application.

The properties of coextruded tubing help produce a laminar structure that allows each layer to contribute a key property to the performance of the tubing, according to a 2017 study in the Fluoropolymers Applications in the Chemical Processing Industries journal. Separate extruders are typically required for the distinct material in coextrusion tubing.

Materials typically associated with coextrusion include silicone, polypropylene, polyethylene, nylon, polyurethane and high-performance resins.

Coextruded tubing can also be used in air purification, semiconductors, water purification and fiber optics.

Some companies in the coextruded tubing space include Raumedic, Putnam Plastics, Lubrizol and Zeus Inc.