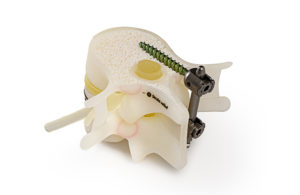

A Stratasys 3D printed anatomical model of a spinal pedicel screw insertion (Photo courtesy of Stratasys)

Stratasys Direct Manufacturing now offers anatomical modeling and consultative services for the healthcare industry.

The Stratasys (NASDAQ: SSYS) subsidiary opened its new Healthcare Print Center in Eden Prairie, Minnesota, and soft-launched the new offerings with an invite-only beta test for medical device manufacturers. Over the past 13 weeks, Stratasys J750 Digital Anatomy printers have created more than 1,000 models, with each printer running more than 120 hours per week.

The printers build life-like medical and dental anatomical models for medical device manufacturers and healthcare providers to use in device testing, medical training, or surgical preparation and consultation. Stratasys launched the printers in 2019 and updated them with biomechanically realistic bone capabilities in 2020.

“The J750 Digital Anatomy Printer can produce models that mimic the biomechanical properties of bone, vasculature, and organ tissues, allowing customers to recreate pathologies not accommodated by cadavers or animals,” Stratasys said in a news release.

“We can now provide companies with previously limited access to these printing capabilities the ability to utilize Stratasys Direct’s manufacturing services to 3D print anatomical models that meet their exact specifications,” Stratasys Americas President Rich Garrity said in the news release.

Stratasys said it also now offers full-service anatomical model design and consulting services, including design transfer and process validation.

Stratasys has dual headquarters in Eden Prairie and Rehovot, Israel.